New

Finishing Options

New

Finishing Options

New

Finishing Options

New

Finishing Options

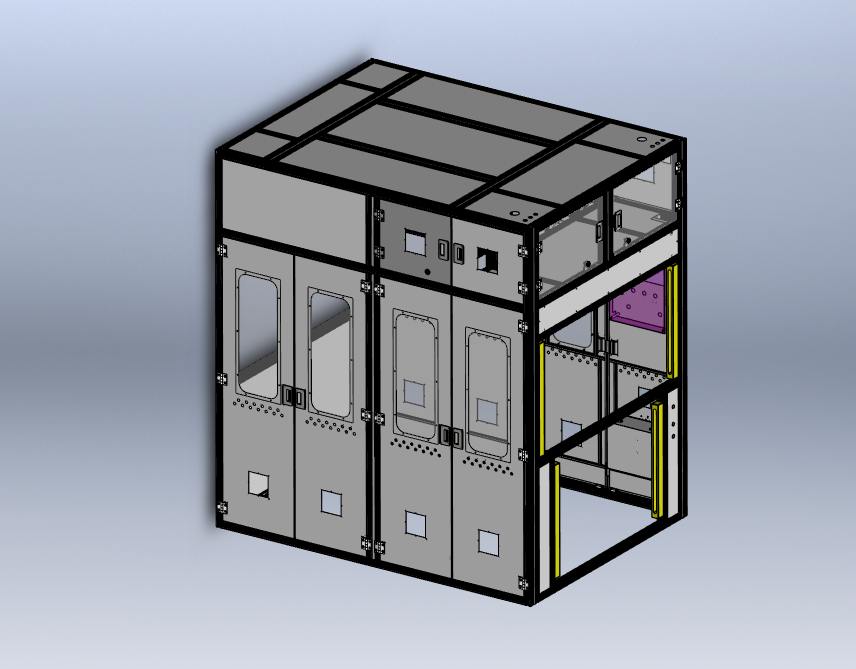

Metal is adaptable that can be progressed into various structures through bowing, cutting and forming it in an assortment of ways. Custom Sheet Metal One of the most common ways that this is done, would be to use custom sheet metal. This tells us that metal components are tailored to our requirements and designs. Many places require custom sheet metal, such as in hospitals where equipment may need to be autoclaved and sterilized regularly before use.

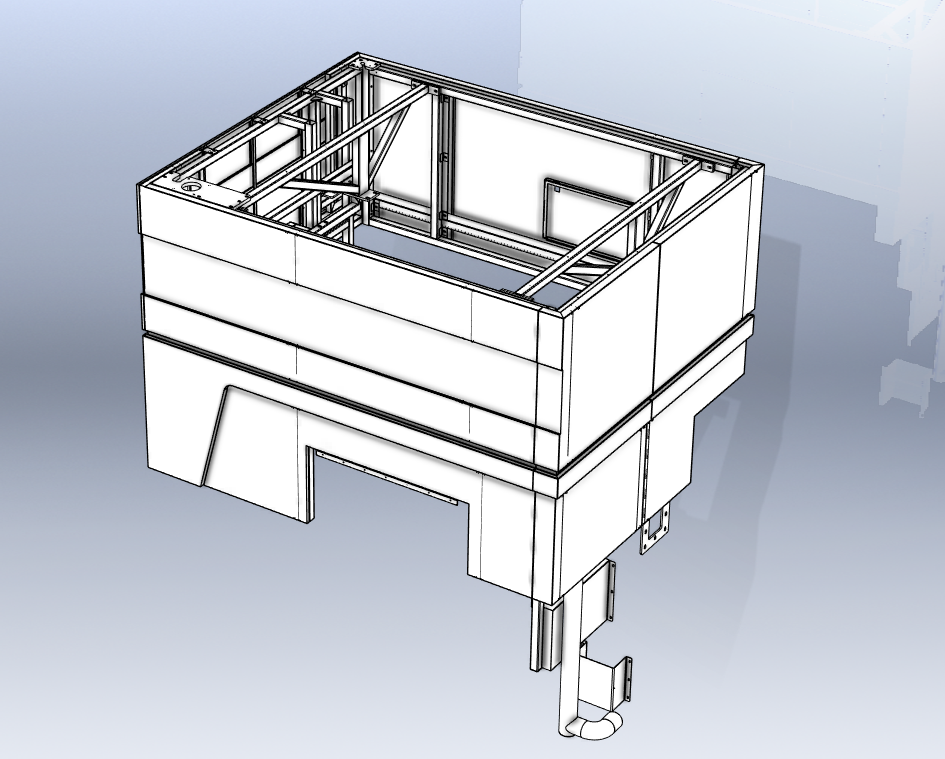

By making different drawings, workers wish to form other types of metal stuff. This drawing is a blueprint that tells everything how the end product should look like. Once they have the drawings prepared, this will enable the skilled machinist to utilize custom sheet metal and cut it in very busy forms into specific dimensions. Producing metal products that are to a high level of accuracy requires more than just good raw materials, it also involves practice and experience in crafting the ideal shapes. The closer the workers are checking, better will be final product.

Metal plates custom designed to provide a large number of things is essential for the production of several tools. These can range from exquisite pieces of jewelry, to parts for planes and even components used in the construction of bridges and buildings. The requirements of certain designs and the high-quality products that are required really lend themselves to custom sheet metal. And to do this correctly, the workers must select exactly what type of metal they need and determine how thick if necessary or not that may be depending on the dimensions. They also refine this eye for design so that each of their unique parts fit flawlessly where they need to be.

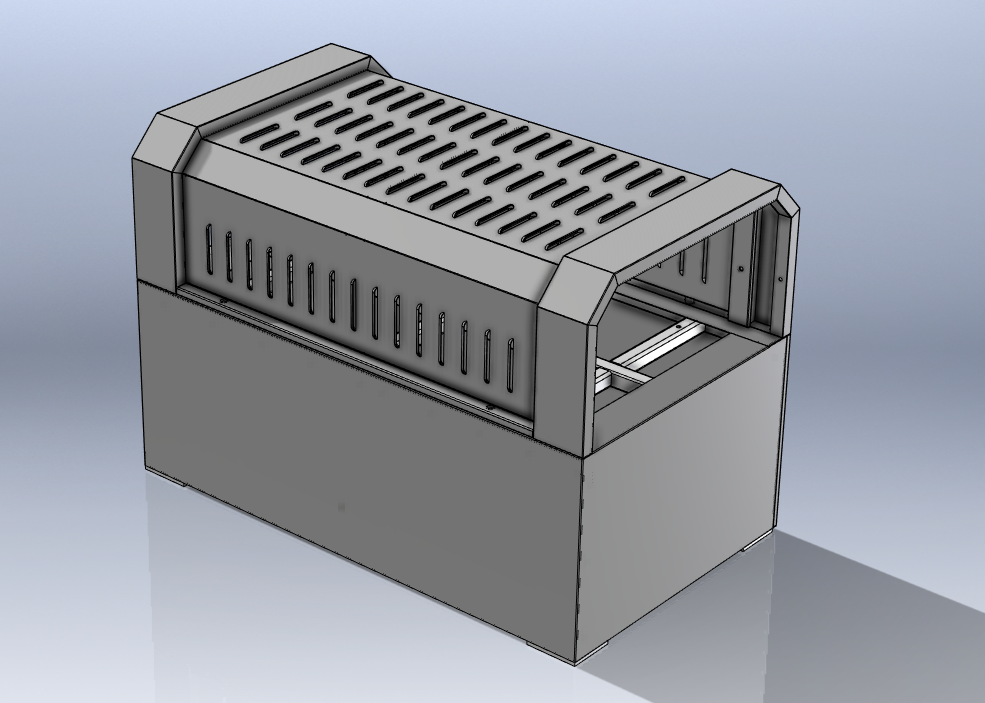

It is good thing for manufacturing a variety of products made custom sheet metal. It is interchangeable and moldable according to a lot of designs There are a lot of kinds of metals and what makes it easier to decide for the right metal is its features. Different metallic substances exhibit different properties, such as some are stronger than others, while less weight or more flexible. This wide choice allows manufacturers to track down the metal most suitable for what they aim to manufacture.

For every custom sheet metal project, you need the assistance of a good design. A design will almost always look the way you want because it was well thought out. Custom sheet metal is ideal if you need to create a large number of products in one go, which can be useful for businesses that require several items fast. Workers can produce numerous sheets or parts over a small period, which makes it simpler to complete big orders in time.

Custom sheet metal is the best option for many who love to do their creative side some good as it allows them more creativity creating new designs which might be a bit hard using other methods. There is a lot of freedom and creativity in the use due to teh types of metals which are available. Their detailed and specific shapes mean they can accommodate intricate designs and parts. The flexibility also allows the workers to form more intricate designs that are not possible with other materials, resulting in new products.