New

Finishing Options

New

Finishing Options

New

Finishing Options

New

Finishing Options

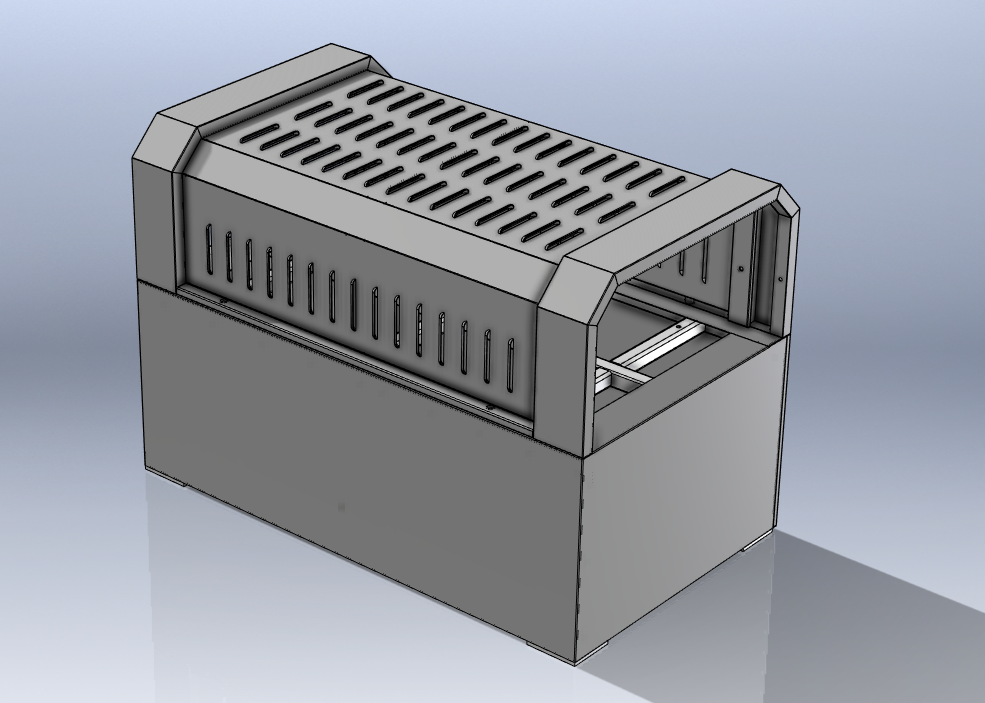

Sheet metal fabrication is an intriguing treatment requiring numerous type of strategies to fashion a sheet metallic aspect. They are of enough importance in many fields, Construction industry is one that cant access with these objects. Sheet Metal Process and Skills The manufacture of sheet metal products is a process that requires skill, care and attention to detail. So now, today - we will plunge further into this wonderful world and know a bit more about how all this works!

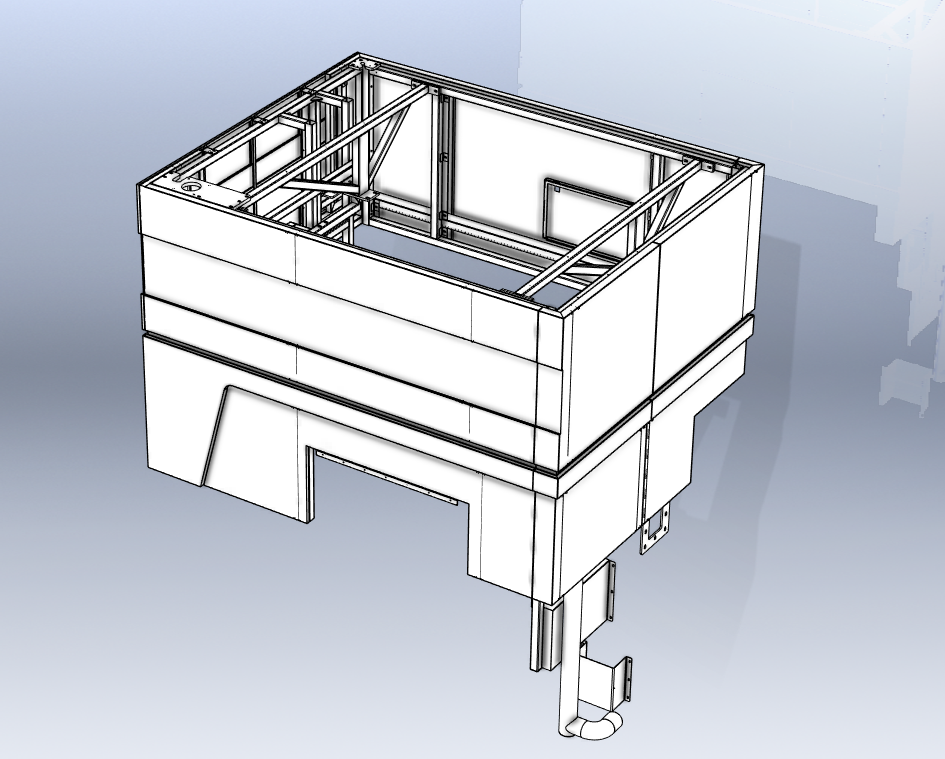

Cutting and bending are two of the most important processes in sheet metal manufacturing. The workers cut the metal sheets with help of special tools called shears and machines known as slitters afterward different sizes, shapes are made. As the metal sheets are quite thin cutting is a skill very much required. Workers can easily damage these or fold them the wrong way if they are not careful.

Another essential step in the manufacturing of sheet metal products is bending. Angles or curved shapes in the sheetmetal are produced by workers using a bending machine. Bending is a process that requires skill just like cutting. The workers work with precision to ensure the findings are just right that they look and function correctly.

Once the raw materials are accepted, special cutting tools cut metal sheets into sizes. Having cut the sheets, they are then formed and bent by the use of a bending machine. The above steps are required to convert the flat sheets into three-dimensional objects. The sheets are carved and bent, then welded into place to form the final product. How does Welding help a product to be Strong and Durable?

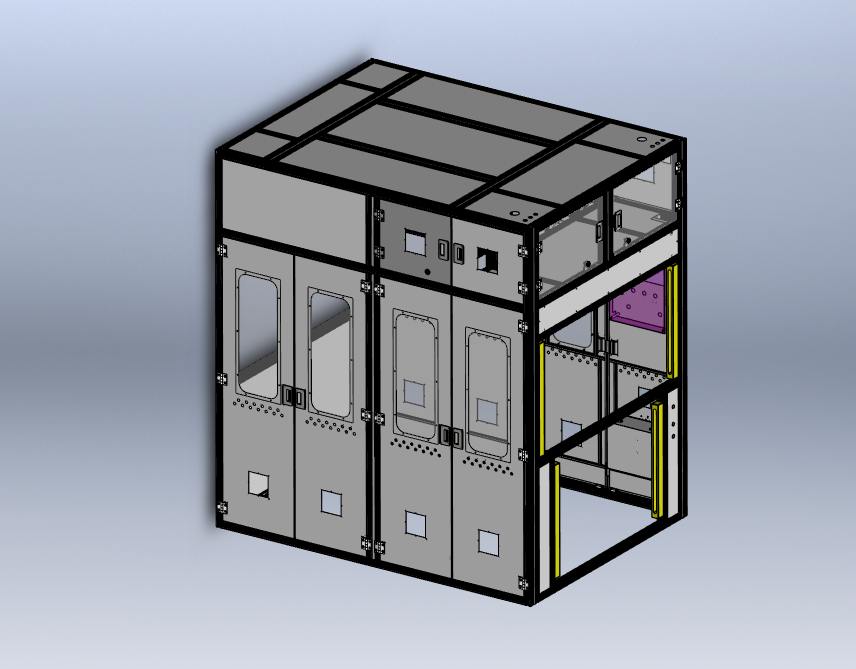

Sheet metal manufacturing quality control is the crux of the matter. This means that each phone must be inspected with great care to guarantee consistent build quality. They are looking for some non-conformity and whether the proper proportions or any of these angles/corners are correct. The process is in place to catch whatever non-conformances that must and will occur during manufacture.

It ensures that the last result is both effective and satisfies industry requirements with quality control. A product that fails the quality check can be either repaired or disposed of before it is delivered to customers. This step is critical to maintaining high quality and protecting the integrity of our products going out to customers.

Sheet metal in the automotive industry Its inclusion in vehicle-related body work and other parts is mandatory. Here aluminum is great for the job, but if we cannot use it then sheet metal and its strength and resilience are perfect for these applications making sure cars stand strong with people inside them.