New

Finishing Options

New

Finishing Options

New

Finishing Options

New

Finishing Options

Sheet Metal: Used to Make Cars + Thousands of Other Products Sheet metal is a thin piece that we can use it with many ways such as cars, appliances like refrigerators or other items furniture and also houses. There are steps that need to be carefully followed in making sheet metal,Schema Of Making The Sheet Metal This guide will teach us everything we need to know about sheet metal fabrication including how it is done, what processes are critical in the design, and why precision work matters.

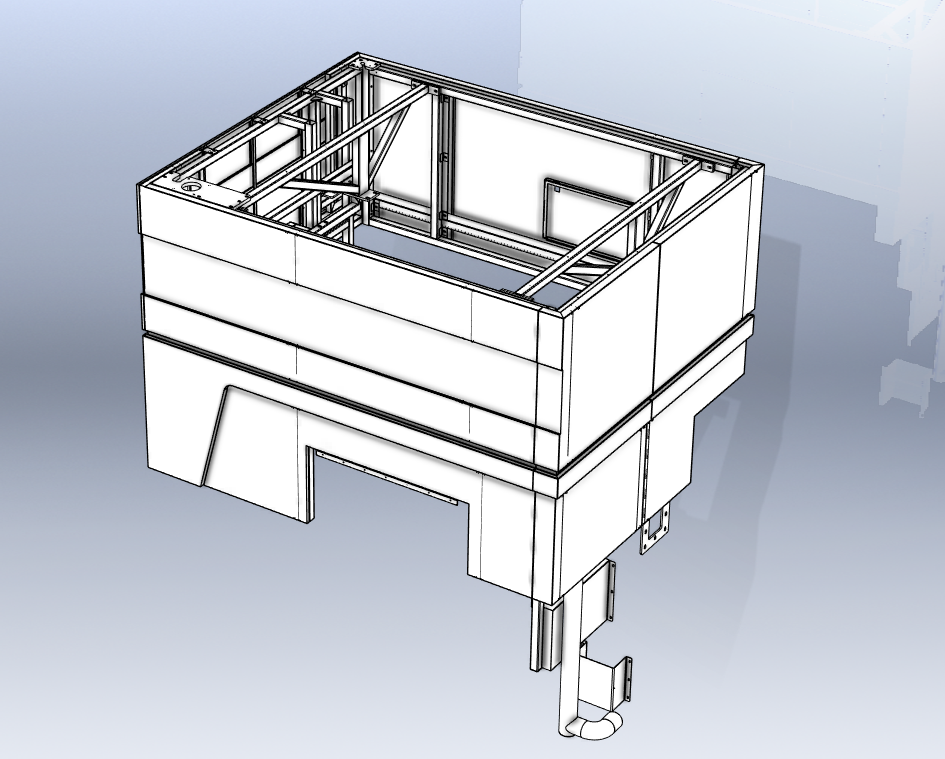

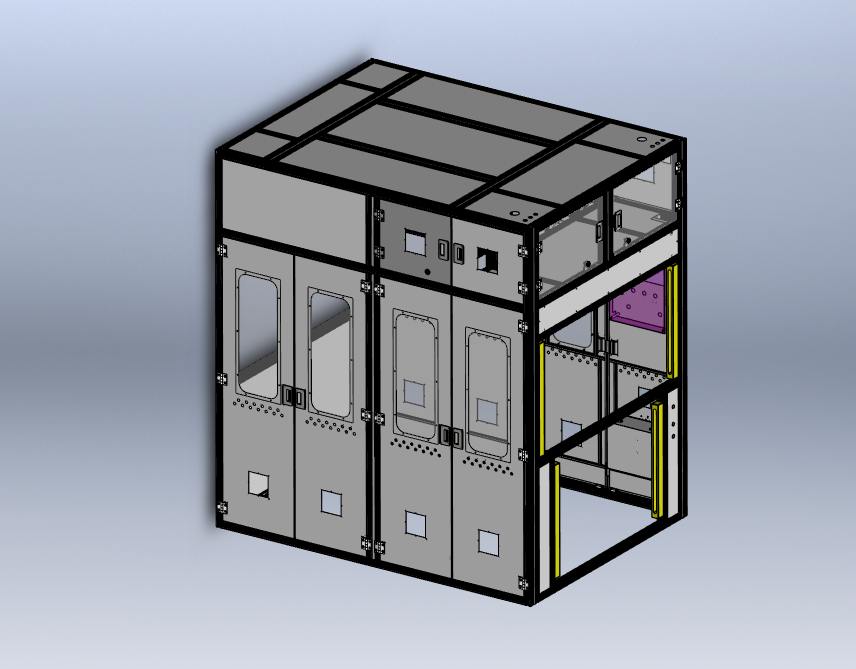

Step 1: Designing the ProductDesign- First Step is design before we can make anything. It allows us to imagine and defining how the item should be, more like its height or shape etc. Designers typically prepare the design using drawings, or use computers to create an accurate image.

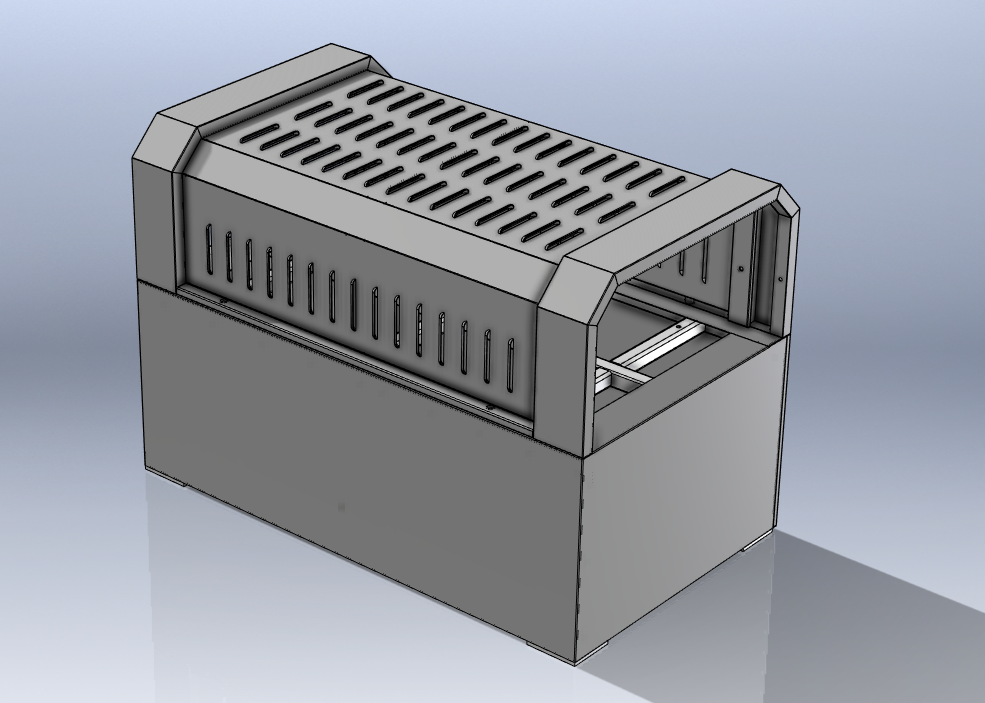

Panel Cutting: With a design in hand, the metal is cut from stock to near-form shape (sheet or panel). Scissors are used by workers for thinner sheets, while thicker metal pieces tend to be cut with a laser cutter. That the cuts have to be quite accurate so that they connect correctly afterwards.

It can bend and shape: The metal bends easily. At this stage, we take advantage of tools like presses and hammers to mould the metal accordingly. Which is so crucial, we want the metal to exactly ditto our design. At times bending a piece of metal may require some workers to do it over and over again until perfect.

Welding and Assembly: Welding is the process of joining two metal objects with each other. The way we achieve this is through melting them down and gluing it all in place. It is very important as it forms a strong sense of Connectedness. We bring all the pieces together to assemble them into an after-weld full unit. Licensed professionals workers must ensure everything goes together correctly before finishing.

Sheet metal is a type of manufacturing material such as aluminum, steel or copper. Different metals have different properties and we would choose them based on what was being made. It is a multi-step process involving cutting, punching bending, and welding. It will be available however we need it and the material type as well as thickness will determine how forcefully or not so much powerfully made. For example, you will have to use powerful tools in order to cut and shape a thicker metal.

Sheet metal production is both a meticulous process and one where even the smallest detail must be taken into consideration. We need to ensure from Top to Bottom of the event is done correctly. Workers are expected to supply materials which are forceful in strength and sizes. Even a single small mistake can turn the entire product into one which is defective or not working properly.