New

Finishing Options

New

Finishing Options

New

Finishing Options

New

Finishing Options

Sheet metal: This product sheet is using a unique kind of steel material which can create numerous products. Thin and flat, it is capable of being cut to fit any shape or size. This is one of the reasons why manufacturers love sheet metal so much. It is popular due to the fact it durable and can be long-lasting resistant whilst at precisely exactly same period stays luminescence. By reading this text, we will come to know How sheet metal products are made uses of Sheet Metal The future way in making things Eco-friendly Making Aesthetics And Functionality CorbesDesign peculiar designs-duty Really?

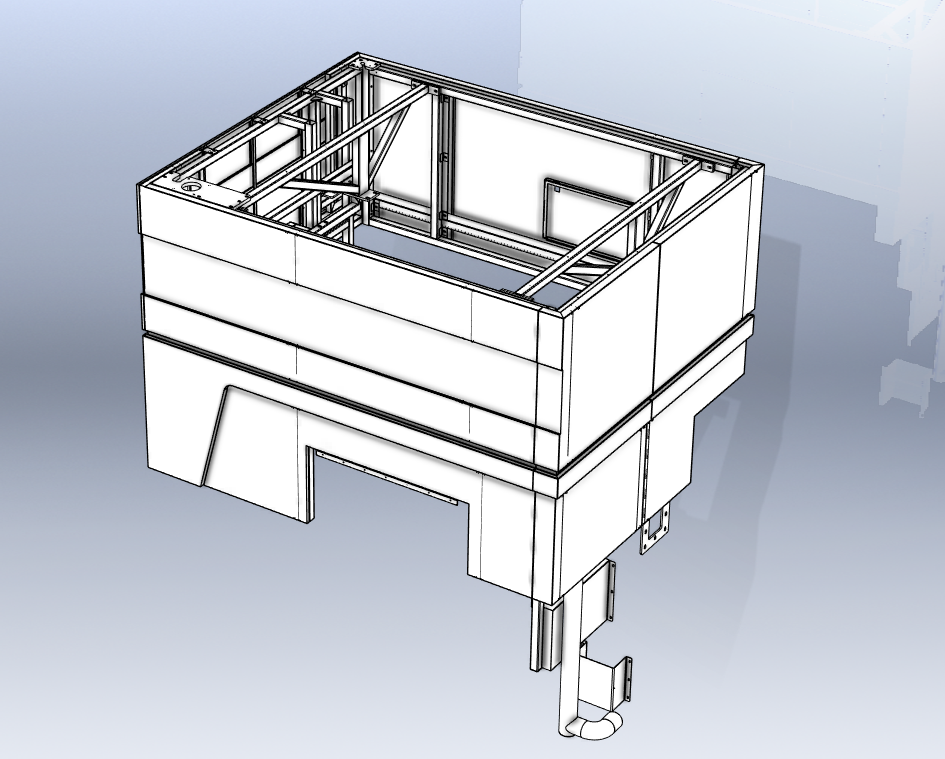

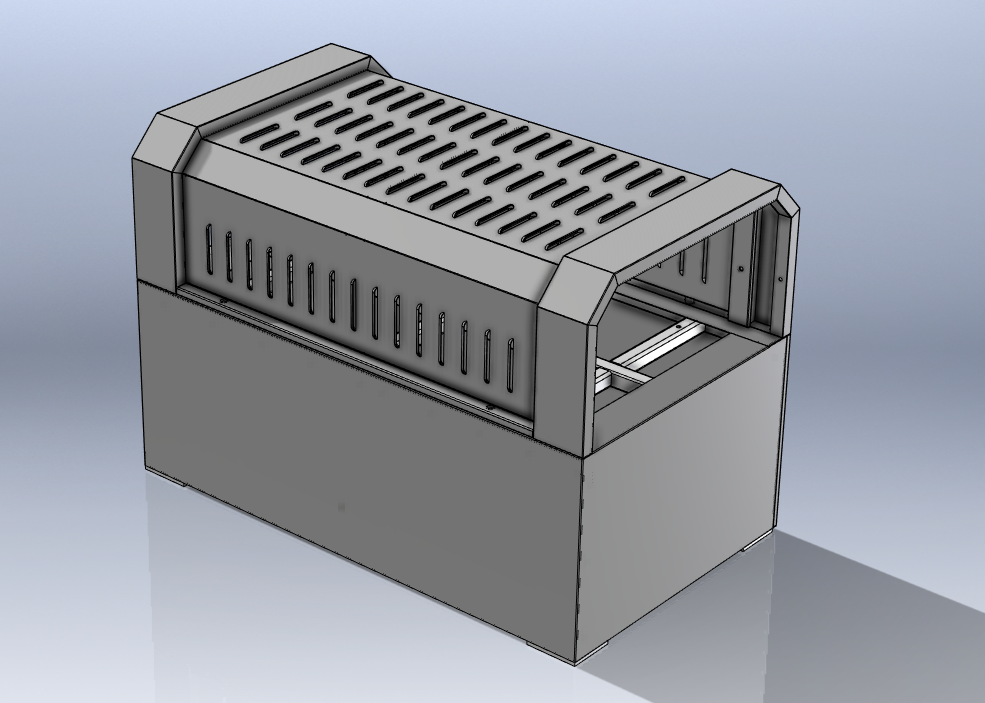

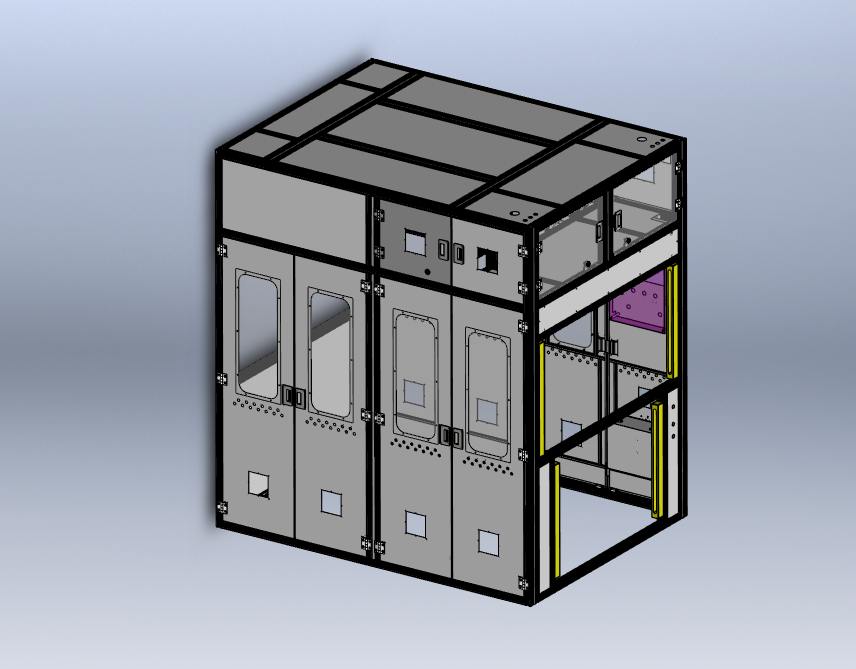

Some of the methods used in order to prepare products from sheet metal include cutting, bending and moulding it into its final form. These processes are carried out with spatial tools and machinery to help craftsmen get the shape they want. Some examples of these tools are shears, this cuts the metal, Brakes bend it, Rollers help to shape and Pressure machines that is used for making final Product. A specially-cutting tool with a sharp blade is used to make very clean cuts in the foam material so that all pieces line up precisely As for the metal being bent, it is inserted into a press brake which uses pressure to bend the metal - forming it into its desired shape. This can be done using a specific machine able to produce elaborate shapes, curves and bends that adapt for numerous designs.

Sheet metal products can be found in nearly every industry, from aerospace to automotive and construction. There are many items in our daily use made up of sheet metal like buildings, bridges, cars and airplanes. They can be used to perform numerous functions such as support, insulation, ducting or transportation of fluid and gases. Sheet metal products commonly used include: the roofs over our heads in buildings, air ducts that allow for us to move and receive fresh air, car body panels which unlike people are protective against road dirt and airborne water; airplane wings (everybody else can safely buy their tickets) enabling them to fly. Sheet metal is known to be versatile and hence one cannot ignore the importance of this product in today's world.

Sheet metal has become ever more eco-friendly over the past years. A lot of companies are trying to reduce the waste and pollution in manufacturing so that energy consumption is also less. Increased use of recycled materials in some organizations that is creating less impact on the environment to produce new goods. For manufacturing to be green, this means ways in which we can lighten the individual demand for energy and materials when making things. So, by adopting this technique a company can not only ensure the preservation of nature (which is so precious), but it also helps companies to create superior quality sheet metal products as per their customer requirements without causing damage to the environment.

Sheet Metal Products...What They Can Do For You : It is always very interesting to me how sheet metal products can find themselves in well almost everywhere. Its shape, what it looks like or how nice something is called the form while its job/benefit people get out of it etc. are function. By form and function we mean something practical, combined with an aspect of beauty. A metal sculpture, for example can be designed to also function as art; it could merely accent space where displayed. Architectural design for the outside of a building can be as nice looking and aesthetically pleasing but still protecting, secure from burglars. Sheet metal products are so desirable largely because of this combination of aesthetics and utility.

A consistent positive aspect of sheet metal products is that they are easily configured to match particular demands. For instance, a company would need a sheet metal cover of exact size and shape to perfectly fit their machinery. Contractors may be required to enter with a type of steel staircase for material coating according local security codes and regulations. Modifying the design of a sheet metal part to suit specific requirements is essential for ensuring its functions properly and [. Customization can mean anything from making the product larger or smaller, rounder or more rectangular to different kinds of finishing and even changing how it functions.